What is CAD?

CAD, or ‘Computer Aided Design’, is the process where computer software is used to digitally create 2D drawings or blueprints or 3D models of real-world products before they are actually manufactured.

CAD is prevalent in industries such as automotive, architecture and engineering, but the process of using CAD software can be applied across many other industries and sectors. It’s a great way of saving time and improving productivity, as well as allowing for scope to improve the end product and the quality of the designs.

How Does CAD Work In Jewellery Design?

CAD is prevalent in industries such as automotive, architecture and engineering, but the process of using CAD software can be applied across many other industries and sectors. It’s a great way of saving time and improving productivity, as well as allowing for scope to improve the end product and the quality of the designs.

How Does CAD Work In Jewellery Design?

In the same way that the use of CAD can apply across a wide range of other industries and sectors, the use of CAD in jewellery creation offers many benefits to designers too.

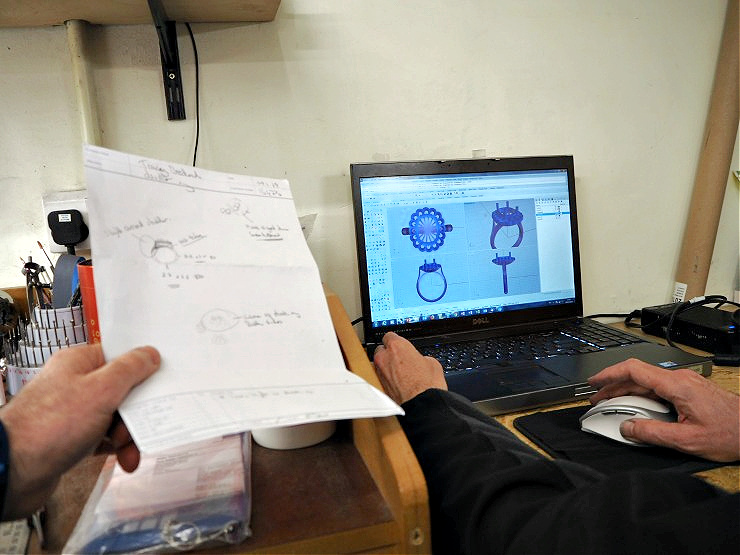

Instead of drawing designs for jewellery by hand, many designers are now turning to CAD for their creative process. Specialist software can allow designers to bring their jewellery to life on screen, or better yet create real-life prototype models so they can get a better understanding of shape and specific components such as mounts or stones. CAD allows designers to create their visions in fine and intricate detail, which is perfect for products as delicate as jewellery such as rings or earrings.

The above process is often referred to as ‘Additive Manufacturing’. This is when a design file is sent to a CD printer or milling machine to create a physical model or prototype. Very fine horizontal layers of material and built up on top of one another until the design is formed. This prototype model, usually made from a form of polymer, can then be converted into a metal master model by the process of casting, also known as ‘Rapid Prototyping’.

What Are The Benefits Of Using Jewellery Design Software?

Instead of drawing designs for jewellery by hand, many designers are now turning to CAD for their creative process. Specialist software can allow designers to bring their jewellery to life on screen, or better yet create real-life prototype models so they can get a better understanding of shape and specific components such as mounts or stones. CAD allows designers to create their visions in fine and intricate detail, which is perfect for products as delicate as jewellery such as rings or earrings.

The above process is often referred to as ‘Additive Manufacturing’. This is when a design file is sent to a CD printer or milling machine to create a physical model or prototype. Very fine horizontal layers of material and built up on top of one another until the design is formed. This prototype model, usually made from a form of polymer, can then be converted into a metal master model by the process of casting, also known as ‘Rapid Prototyping’.

What Are The Benefits Of Using Jewellery Design Software?

There are a range of benefits to using CAD software for jewellery designers. Some of them include

- Faster design: Products can be designed in a much more efficient and time-saving manner as the software allows the designers to create mock-up ideas a lot faster than drawing out 2D designs by hand.

- Error-free production: Using CAD software means there is little room for error, as dimensions and sizes can be properly adhered to during the design process.

- Clear cost projections: Creating real-life models of the products means you have a clear understanding of the amount of raw materials you may need to use when creating your final product and how much creating each piece of jewellery could cost. Clients can also see their products before they are actually manufactured, which means items can be marketed ahead of time and that can help drive customers to make a purchase.

If you want to read more about CAD in jewellery making check out my post here.

No comments